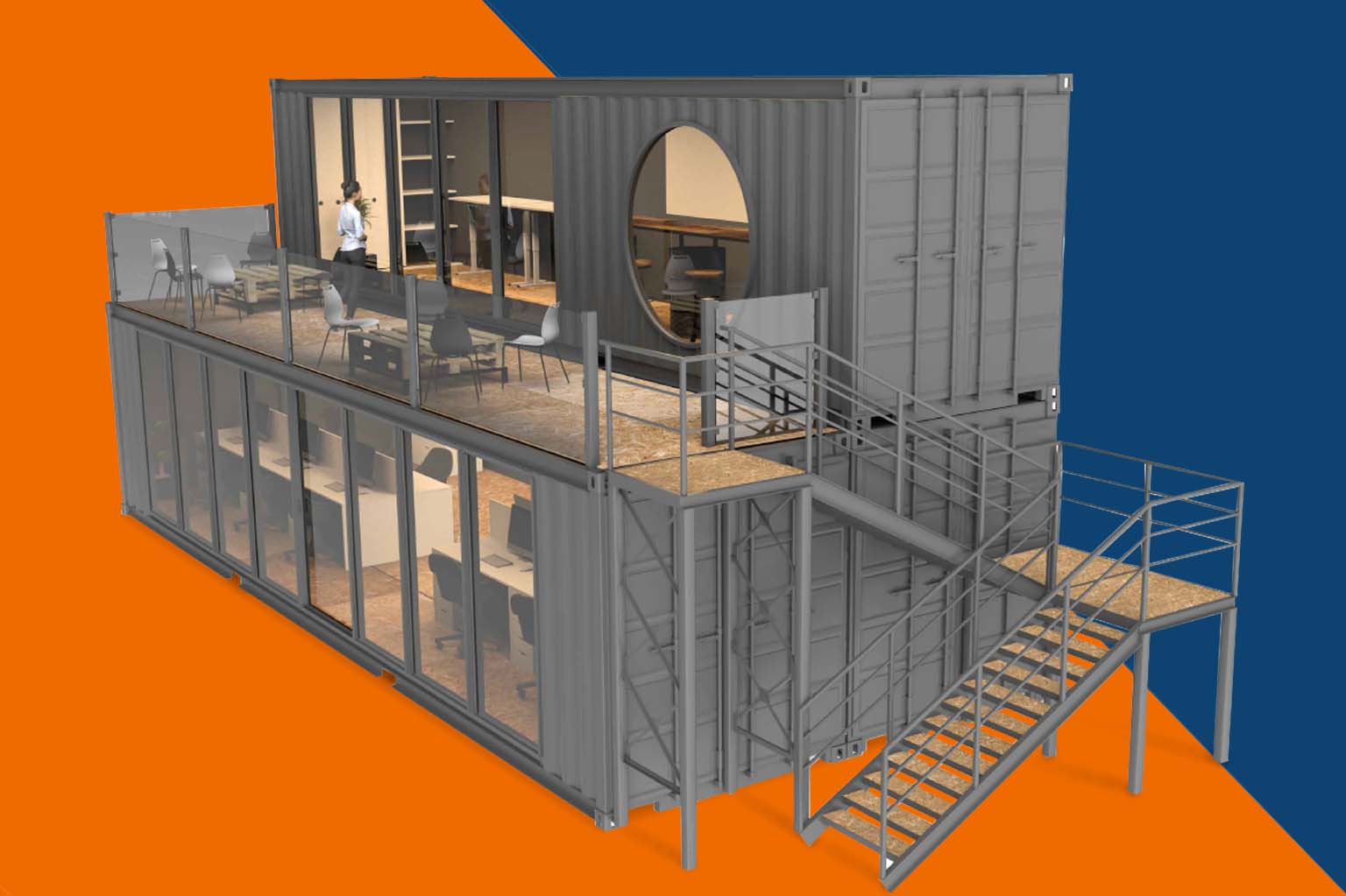

With three x 40ft shipping containers on a building footprint of 90m² we designed, built and delivered this stunning new design studio. The project involved working closely with the client to bring their vision to life. We ensured all their needs were met whilst considering heat efficiency and operating costs.

Once the drawings provided by DS Smith were signed off our engineers got to work straight away. Planning for electrics, flooring, walls, the staircase and so on were carried out with meticulous attention to detail. Keeping the project on schedule and on budget while delivering the highest quality is one of our prime objectives.

Sustainability

DS Smith is a worldwide leading provider of sustainable packaging solutions, paper products and recycling services. The decision to use recycled shipping containers for their new design studio was an obvious one. The benefits are endless. Construction with shipping containers is more cost effective than traditional materials, faster, sustainable and therefore kinder to the environment.

3 x 40ft containers

We sourced three single use 40ft shipping containers. They had been used to transport goods from Asia to Europe. Their new purpose was to be the main components in a new design studio, making them officially recycled shipping containers.

Fabrication

The configuration required the cutting and removing of the the sides from container 1 and 2. Container 3 is stacked atop container 2 and accessed via a mezzanine area. The mezzanine area is accessed using a purpose built steel staircase to the right hand side of the building.

Removal of inner walls required support steel installation and joining bracketry. This creates an open plan area for main lower-level office.

Apertures form lower and upper-level entrance doors. A circular 1.1m diameter porthole style window provides interest and a contrast to the straight lines through the rest of the studio. Ground level openings of 10m x 2.3m provide doorway access while a 5m x 2.3m doorway is the entrance to the first floor area.

Bracketry on the rear side of container 2 and 3 supports the air-conditioning condenser units. All windows and doors have RAL7016 frames installed.

A PPC aluminium centre open door set with fixed windows left and right are installed. 2 x 2.5m x 2.39m PPC aluminium framed fixed glass panels allow plenty of natural light to shine in. The circular window fixed panel is also a PPC aluminium frame.

The glass balustrades fitted to the mezzanine again allows natural light in and views of the surroundings. The toughened glass at a height of 1.1m is 16 linear meters in total and makes for a stylish design feature.

Internals

All internal walls are lined. CLS timber frame with air gap and 50mm rockwool provide excellent insulation. Gypsum board finish throughout taped and jointed creates a clean open space. The floor is overlaid with 18mm OSB finished throughout.

Exterior

For the external walls Jotun conceal marine paint system is installed. The maximises corrosion protection while being aesthetically pleasing.

Staircase

The external staircase provides access to the mezzanine. A steel frame design OSB topped treads and platforms creates a stylish entrance to the upper floor.

Electrical

The electrical installation carried out at our production facility is done to NICEIC standard. A single phase distribution board supplies an external commando socket connection, 18 x LED surface mounted light, 22 x twin sockets, 4 x floor compartment sockets and data sockets PTBC wired back to a data cabinet. The A/C system for cooling and heating consists of two 2.5 kw units.

Delivery

We carried out a site survey prior to delivery. This ensured all logistical challenges were resolved. Delivery to the site via road transport to DS smith was provided with HIAB to off load of all containers. The site was prepared for the delivery of the units with clear access for a HIAB cranes flatbed.

Lead time

We completed the project in 10 weeks, which was on schedule. Furniture, groundworks, service connections on site, building regulation and structural calculations were all taken care of by the client.

Summary

If you have a project you think would be a good fit for us, please reach out to our sales team on the contact form below or call 01606 633018, we’re looking forward to hearing from you!

Further reading

https://inboxprojects.com/container-bike-store-training-whinlatter-forest/1841

https://inboxprojects.com/portable-offices

https://inboxprojects.com/recycled-container-signal-station/1956